Making maple syrup: a photo essay

As we drove by a small sugar house, we saw smoke and steam rising from the vents in the roof – they were making syrup today.

We’d never been to Wayne LaPier and Family Maple Sugar House before, and we’d just come from a pancake breakfast at another maple farm. But the woodpile stacked to the side of the building suggested that LaPier’s was an old-fashioned operation, one that still ran on wood for fuel rather than gas or electric. And a sign out front advertised an open house.

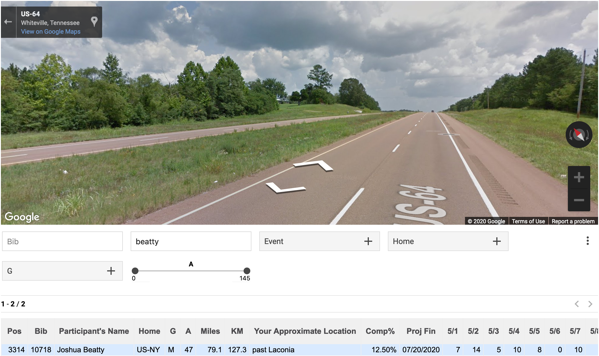

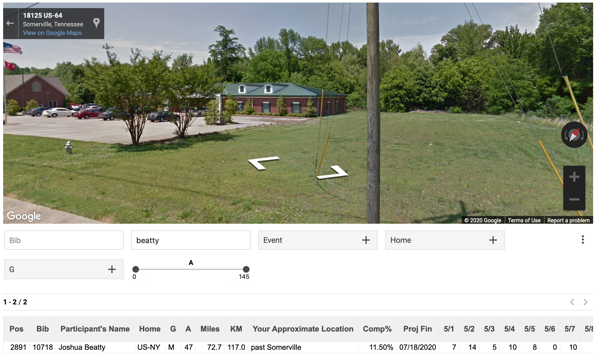

Inside we met Wayne LaPier, 75 years old, who has run this operation since 1985 when he bought it from his father. He’s standing next to the evaporator, the key piece of equipment in making maple syrup, and the producer of the smoke and steam that alerted us a boil was taking place.

Sap used to be collected in wooden or metal pails and then carried to the syrup house. Now a system of plastic tubing connects the trees and gravity carries the sap down to a drum for collection.

Those drums are gathered when they fill, brought to the syrup house, and poured into a larger collection tank.

Sap from nearby trees bypasses the collection drums and is pulled directly into the sugar house via a simple vacuum system hidden in a back closet.

In another closet sits this reverse osmosis machine. It takes the sap from the collection drums and vacuum system and rather like a household water filter, separates the water from the impurities – except in this case it’s the “impurities” that become the syrup. The process cuts the fuel needed for running the evaporator by two-thirds.

After going through the RO system, the syrup is stored in an overhead vat and gradually drained into the evaporator. Wayne bought this evaporator when he took over the operation in 1985. It’s made by the Canadian company Dominion & Grimm. Matthew Thomas’s Maple Sugar History blog has a short history of the firm, including an advertisement from 1909 with an evaporator that looks very much like this one.

There’s a pile of wood ready to be burned.

The rest of the family is moving the wood into place…

…so Wayne can keep the fire going.

Sap boils inside the evaporator, further reducing the water content.

Wayne uses a hygrometer to test the syrup from the evaporator. When the syrup reaches a particular density, it’s nearly ready for consumption.

It only needs to run through a series of filters…

…and the result is fresh, warm syrup, with a flavor much richer than even good syrup that has been packaged and stored.

Reader, should you ever have the chance to drink hot maple syrup right from the evaporator, please, do not pass it by.

Thanks to Wayne LaPier, Christine, and the rest of the family for letting us stay for an hour, answering all our questions, and giving us a taste of the syrup at its best.

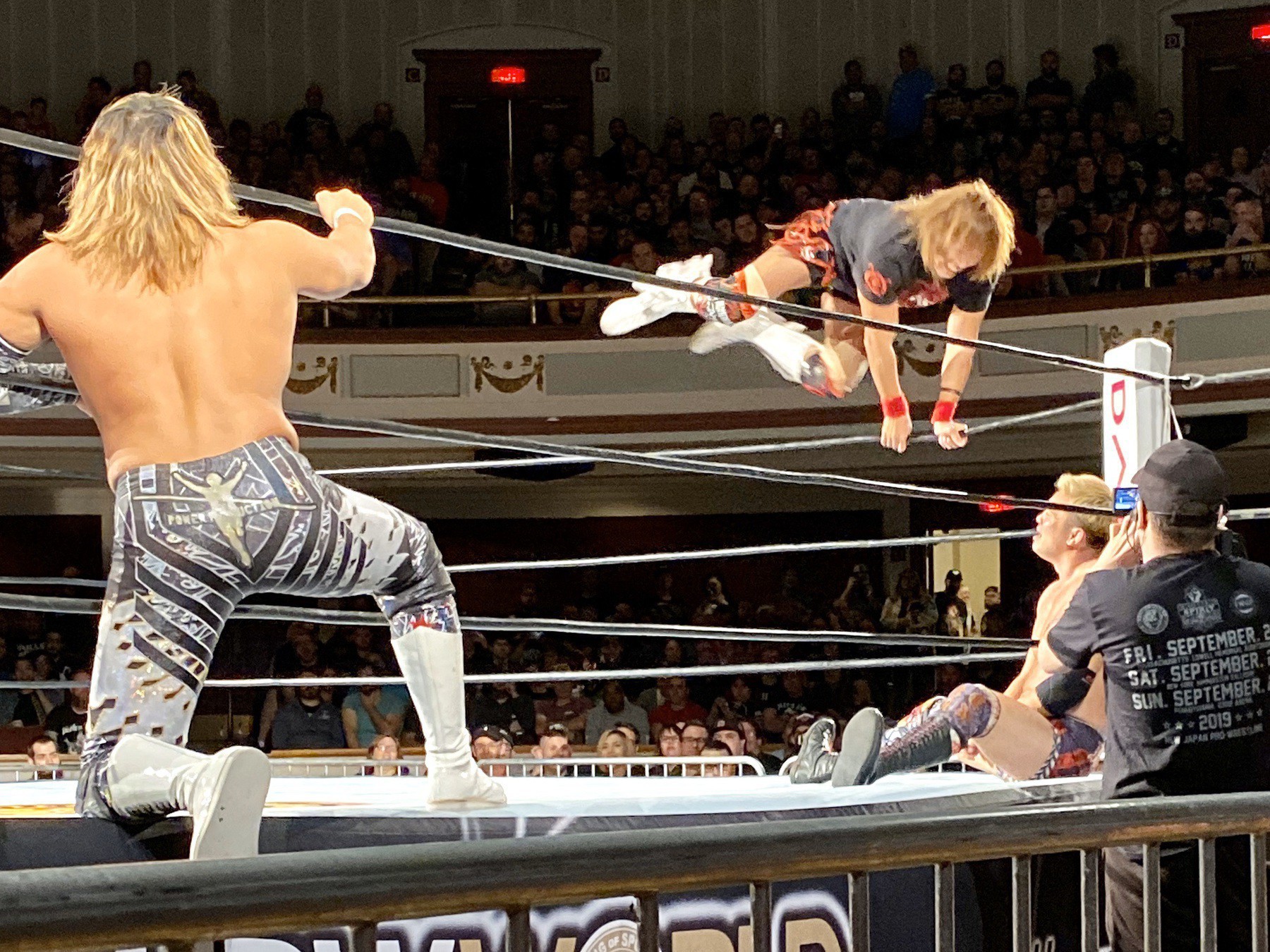

Compare to this one I took with an iPhone XS earlier this year:

Compare to this one I took with an iPhone XS earlier this year:

![mp-photo-alt[]=](https://social.joshuabeatty.info/uploads/2019/10a5cf1148.jpg)